High-Precision Sheet Metal, Delivered On Time.

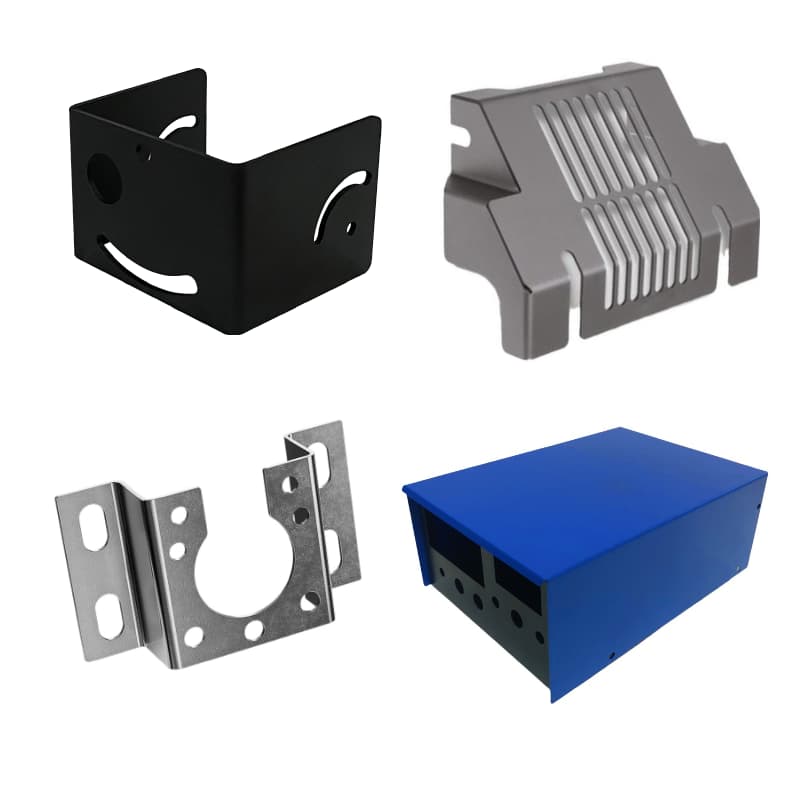

We combine cutting-edge technology with expert craftsmanship to build custom enclosures, brackets, and assemblies that meet your exact specifications.

- Advanced Fiber Laser Cutting

- Precision CNC Bending & Forming

- Full Welding & Assembly Services

Our Core Fabrication Processes

Laser Cutting

Utilizing high-power fiber lasers for clean, precise cuts on a wide range of metals and thicknesses with minimal heat distortion.

CNC Bending & Forming

Our press brakes accurately form complex angles and geometries, ensuring perfect repeatability for brackets, panels, and enclosures.

Welding & Assembly

Offering TIG, MIG, and spot welding, plus hardware insertion (PEM nuts, studs) for fully-assembled components.

Why Partner With Us

Strict Quality Control

Rigorous inspection of dimensions, angles, and finishes at every stage.

State-of-the-Art Equipment

Our investment in modern machinery guarantees precision and efficiency for your projects.

Competitive Pricing

We offer cost-effective solutions without compromising quality.

Reliable Lead Times

From rapid prototypes to production runs, we deliver on time, every time.

Sheet Metal Portfolio

Industry Applications

Robotics & Automation

Consumer Electronics

Automotive

Aerospace & Defense

Medical Devices

Energy & Industrial

Our Fabrication Capabilities

Extensive Material Selection

We work with a wide variety of sheet metals to meet the specific requirements of your project, from structural integrity to corrosion resistance.

Stainless Steel: 304, 316, 430, etc

Aluminum: 5052, 6061, etc

Professional Surface Finishes

Enhance your parts with our comprehensive finishing options for improved durability, functionality, and cosmetic appearance.

Core Capabilities

Our Simple 4-Step Process

Submit Your RFQ

Securely upload your CAD files (STEP, DXF, DWG, etc.) and technical drawings. A dedicated project engineer will be assigned to review your requirements.

Engineering Review & Quote

Your design is carefully reviewed by our engineers for manufacturability. We provide a clear, itemized quote within 24 hours.

Fabrication & QA

Upon approval, your project enters production. We conduct in-process quality checks and a final inspection to guarantee parts meet all specifications.

Final Inspection & Delivery

Parts are securely packaged with all required documentation (inspection reports, material certs), and shipped globally with tracking.

Sheet Metal FAQs

Upload your files for a fast, comprehensive quote from our engineering team.