Your Premier Aluminum Machining Partner

We craft mission-critical aluminum components with unmatched precision and flawless finishes.

- Uncompromising Precision & Tight Tolerances

- Specialized Expertise in Aluminum

- Flawless Surface Finishes

Our CNC Machining Capabilities

CNC Milling

3 Axis, 4 Axis and 5 Axis CNC Machining Service for simple and complex geometries parts.

CNC Turning

CNC turning with live tools combines lathe and milling capabilities to machine parts with cylindrical features.

Finishing Services

Add multiple finishes to your parts, such as Anodizing, Sand Blast, Powder Coat, Plating, etc.

Why Choose RONGXU

Expert Craftsmanship

Deep expertise in aluminum with flawless finishes and tight tolerances.

Advanced Technology

Our 3, 4, and 5-axis CNC machines deliver consistent quality and reliable precision.

Rapid Turnaround

From fast prototypes to on-time production runs, we accelerate your schedule.

Dedicated Support

Our dedicated team is here to ensure your project's success every step of the way.

Milling Centers

Our multi-axis milling centers allow us to produce highly complex parts with intricate geometries in a single setup, ensuring maximum precision and efficiency.

Turning Centers

Equipped with live tooling and Y-axis capabilities, our lathes produce high-accuracy cylindrical parts with complex off-center features, reducing lead times.

Inspection Equipment

Our investment in advanced metrology guarantees that every part we ship meets the tightest tolerances and conforms perfectly to your specifications.

Our commitment to investing in leading technology is a direct investment in the success and quality of your project.

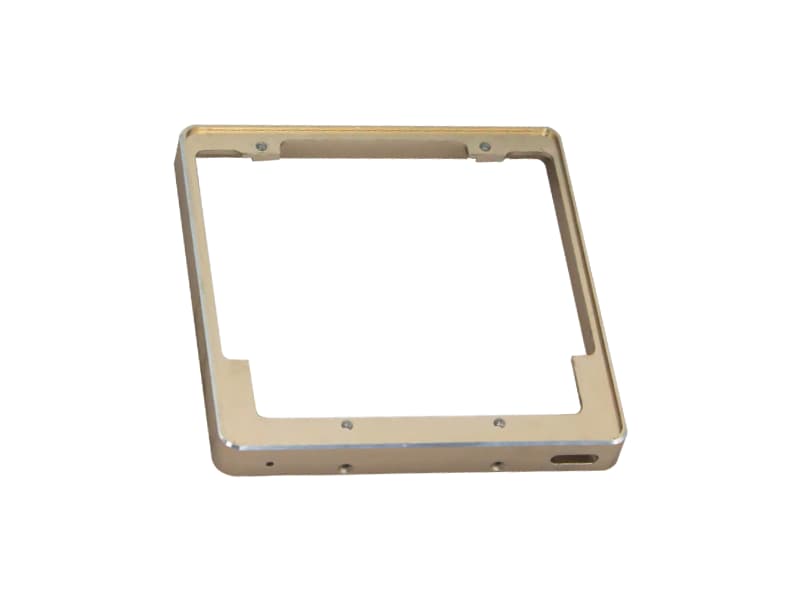

Our Portfolio

Industry Applications

Robotics & Automation

Consumer Electronics

Automotive

Aerospace & Defense

Medical Devices

Energy & Industrial

Our Customization Capabilities

Extensive Material Selection

We specialize in aluminum but are proficient with a wide range of metals and plastics to suit any application.

Steel: Stainless (303, 304, 316L), Alloy (4140), etc.

Plastics: PVC, PEEK, Nylon, PC, ABS, etc.

Professional Surface Finishes

We offer a comprehensive range of surface treatment solutions to achieve optimal aesthetics, corrosion resistance, and surface performance.

Core Capabilities

Our Simple 4-Step Process

Submit Your RFQ

Securely upload your 3D CAD files (STEP, DWG, etc.) and technical drawings. A dedicated project engineer will be assigned to review your requirements, ensuring full confidentiality.

Engineering Review & Quote

Once submitted, your design is carefully reviewed by our engineers. We will respond within 24 hours, and then provide a clear, itemized quote with no hidden fees.

Manufacturing & QA

Upon approval, your project enters production. We conduct First Article Inspection (FAI), in-process quality checks, and a final inspection to guarantee parts meet all specifications.

Final Inspection & Delivery

Parts undergo a final verification, are securely packaged with all required documentation (inspection reports, material certs), and shipped globally with tracking.

CNC Machining FAQs

Upload your files for a fast, comprehensive quote from our engineering team.