Instrument Chassis

| Feature | Description |

|---|---|

| Machining Services | 3/4/5 Axis CNC Milling, CNC Turning, Drilling, Laser Cutting, CNC Bending & Forming, etc. |

| Material | Aluminum Alloys (Our Specialty) 6061, 6063, 7075, 5052, 6082, etc.; Stainless Steels (303, 304, 316L), Alloy (4140), etc.; Plastic (PVC, HDPE, Nylon, PC, ABS, etc.); Other Metals: Brass, Copper, Titanium, etc. |

| Surface Finish | Offering comprehensive surface treatment options, including: Anodizing (Type II & III), Bead-Blasting, Powder Coating, Polishing, Brushed, Spray Painting, Laser Engraving, Silk-Screen Printing, etc. |

| Part Size Range | Strictly processed according to customer drawings. |

| Tolerance | Standard ±0.10 mm | High Precision ±0.02 mm |

| Applications | Automotive Components, Consumer Electronics Enclosures, Instrumentation, Aerospace, Defense, Medical Devices, Robotics, Industrial Automation, Communications, Power Supply Systems, etc. |

| Core Service Feature | 1. Offering highly competitive prices 2. Providing DFM (Design for Manufacturability) analysis to optimize design 3. Full Project Lifecycle Support, offering professional support from initial inquiry to subsequent bulk orders and after-sales maintenance 4. Flexible Capacity: Seamless connection from rapid prototype to stable mass production |

| Inspection | Rigorous 100% inspection procedures, conducting comprehensive dimensional checks on all parts to ensure full compliance with your specifications. Inspection reports are complete and fully traceable. |

| Testing Equipment | Three-Coordinate Measuring Machine (CMM), 2D Vision Systems, Height Gauge, Micrometer, Roughness Tester, Specialized Gauges, etc. |

| Quality Guarantee | Inspection reports and material certification are available, with commitment to provide rework or refund for quality defects caused by our side. |

| Payment | Supporting T/T, L/C, etc. Specific terms can be negotiated based on order size and customer credit. |

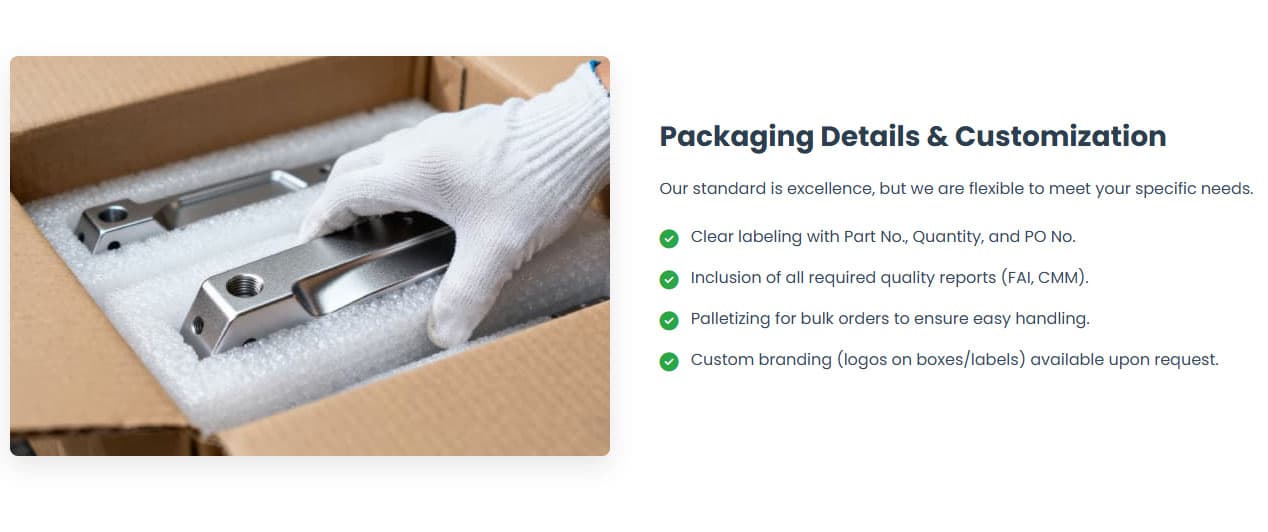

| Packaging | Paper/PE protective film, custom EPE foam, corrugated cartons, and fumigated wooden crates/pallets as required. |

| Delivery Time | Flexible Scheduling & Expedited Options. Lead time is stable and reliable, usually completed within 10-20 days, specific time determined by order complexity and quantity. |

| Drawing Format | CAD file (dwg, dxf, pdf, etc.), 3D file (step, stp, etc.). |

| Response Speed | Provide formal drawings (specifying material/quantity/surface treatment, etc.), the quotation sheet will be sent within 24-48 hours. |